From AIOps to AgenticOps: The Autonomous Evolution of Firewall Operations

September 18, 2025

The 80/20 Rule Doesn’t Apply to Security: How Cisco SASE Bridges the Gap

September 22, 2025Honoring Autodesk customers’ groundbreaking achievements: Design & Make Awards 2025

- With the Design & Make Awards, Autodesk honors innovation, achievement, and sustainability.

- The awards feature groundbreaking projects across industries and around the world.

- The event showcases how Autodesk software pushes boundaries and inspires designers and makers.

Autodesk customers worldwide continue to push the boundaries of what’s possible, driving innovation even further and delivering meaningful impact. At AU 2025, we honored some of these inspiring customers and their work across Architecture, Engineering & Construction (AEC), Design & Manufacturing (D&M), Media & Entertainment (M&E), Education, and the Autodesk community.

This year, we received an outstanding 320 submissions from 48 countries. From this remarkable pool, 22 winners were selected showcasing the diversity and creativity of our global community. We are grateful for their contributions in advancing industries, strengthening communities, and making a positive impact on the world.

Architecture, Engineering & Construction (AEC)

Innovator of the Year: JT+Partners

As part of Dubai’s Vision 2030 plan, the emirate is targeting 25% of all new buildings to be constructed using 3D printing technology. JT+Partners has embraced this goal with the first-ever 3D printed mosque in Dubai, a 2,000-square-meter structure set to welcome 600 worshippers by 2026. Autodesk Platform Services, Navisworks, and BIM Collaborate Pro were critical to making it possible. Guided by a precise digital model and built with mineral-infused materials, the project will reduce material waste by more than 60% and cut transport emissions by 30%, all while enabling intricate design features.

Rendering of JT+Partners’ 3D-printed mosque design. Courtesy of JT+Partners.

Accelerating Transformation: Metro Istanbul

Metro Istanbul operates on an enormous scale with 18 train lines, 235 stations, and hundreds of thousands of interconnected assets. To manage this complexity, the organization is pioneering a digital twin initiative powered by Autodesk Tandem and Tandem Connect, capturing everything from trains and transformers to escalators and even light bulbs. By integrating real-time data with a station’s BIM model, they’re demonstrating the huge impact of a smart, responsive system. Metro Istanbul can streamline maintenance, optimize energy consumption, and make better, data-driven decisions.

Making a Better World: ScottishPower

SP Energy Networks, part of the ScottishPower group, is supporting the UK’s clean power goals for a 2030 carbon-free grid and a net-zero economy by 2050. The company is building substations that draw energy from new wind farms and renewable sources, storing it in large-scale battery banks capable of powering millions of homes. A digital twin of the network will further enhance how assets and electricity are managed. To deliver this transformation, SP Energy Networks is using Autodesk Construction Cloud, Revit, Civil 3D, InfraWorks, Tandem, and other tools, all connected through Autodesk Platform Services. With these investments, they’re accelerating progress toward a cleaner, more resilient energy future.

Infrastructure Design: TPF

A transformational, 1,300-kilometer rail line in Brazil will deliver new connections and economic opportunities from an inland agriculture hub to the port of Paranaguá. For the Nova Ferroeste rail line in southern Brazil, TPF turned to AI to find the optimum route. With Autodesk Civil 3D and InfraWorks, they were able to cut track modeling time from a year to just four months. The completed line is projected to reduce transportation costs by 20%, shorten travel time by 80%, and lower energy use, emissions, and congestion by up to 35%. TPF’s innovation showcases how technology can transform not just infrastructure, but its impact.

Building Design: Warren and Mahoney

The Te Rua Archives in Wellington, New Zealand, is designed to both safeguard culture and withstand disaster, with resilience against major seismic events and co-design input from mana whenua, Māori advisors with ancestral ties to the land. Warren and Mahoney led the project using Autodesk Revit and BIM 360 for coordination across five cities, Forma and Insight for environmental analysis, and Workshop XR for enhanced stakeholder collaboration. When complete, the archives will protect vital national documents and taonga—treasured Māori artifacts—demonstrating how a structure can be rooted in history, shaped by culture, and strengthened by innovation.

Rendering of the Te Rua Archives in Wellington, New Zealand. Courtesy of Warren and Mahoney.

Construction: Boustead Projects

Collaboration is the heart of a successful construction project. For a new semiconductor facility in Singapore, Boustead Projects made even further collaborative inroads with Autodesk Construction Cloud as the common data environment. Precision is everything when building a semiconductor facility, and using 4D BIM, LiDAR scanning, and photogrammetry helped the team reduce clashes by 60%, cut rework by 20%, and improve overall efficiency by 30%, despite changes in scope mid-project. The result was not just an impressive facility, but a truly collaborative project ecosystem

Autodesk Platform Services: Lantis

The Oosterweel Link is a massive undertaking designed to ease congestion around one of Europe’s busiest ports. By adding new tunnels and connections, the project aims to reduce bottlenecks and separate heavy port traffic from daily commuters. Lantis is leveraging a fully integrated data environment—powered by Autodesk Platform Services—to link information from design and construction all the way through to operations. This seamless flow of data ensures the infrastructure isn’t only built efficiently but managed intelligently throughout its lifecycle.

Design & Manufacturing (D&M)

Innovator of the Year: Fellten

Fellten is reimagining automotive heritage by converting vintage gas-powered icons, such as Porsches, MINIs, and Land Rovers, into fully electric vehicles. Without altering the chassis, Fellten installs engine-shaped batteries that bolt directly into place, preserving the car’s balance, handling, and unmistakable character. Fusion powers every step of the process, from CAD modeling to cloud collaboration. Fellten can turn concepts into prototypes in just three months and expand their products to include boats, mobile chargers, and energy storage solutions for electric fleets.

Fellten’s innovative battery system turns vintage cars into clean electric vehicles. Courtesy of Fellten.

Accelerating Transformation: Ford

As cars become as much about electronics as mechanics, prototyping those systems is more critical now than ever. Ford’s Experiential Prototyping team uses PCB design tools in Autodesk Fusion to create fully custom, functional prototypes. The team designs and refines sophisticated PCBs and wiring systems years before production, enabling prototypes that truly forecast future vehicles. From luxury SUVs to revolutionary concepts, they can move from proof-of-concept builds to refined, production-ready systems in days or weeks, not months or years.

Making a Better World: Last Energy

Last Energy is on a mission to transform nuclear plants from complex construction projects into a mass-manufacturable and plug-in-play product. By productizing nuclear energy, Last Energy can help power the massive energy needs of new data centers fueling the AI boom. They’re leveraging the Autodesk Design & Make Platform to do everything from conceptual design and engineering validation to prototyping and immersive design review. Last Energy’s modular 20-megawatt nuclear power plants can be installed in just 2 years and 80% faster than traditional nuclear projects, paving the way for clean energy faster.

One of Last Energy’s modular nuclear power plants under construction. Courtesy of Last Energy.

Product Engineering and Manufacturing: Rokion

Rokion designs electric vehicles for industrial uses, where issues of safety and reliability matter as much—or more—than performance. With Autodesk Inventor and AutoCAD, Rokion trims design-cycle time and speeds new models to market without sacrificing quality. Vault keeps every project and part perfectly organized as designs evolve. Through better design and data management, Rokion is helping to create the future of industrial mobility.

Digital Factory Innovation: DYD

For the design of a new Volkswagen electric vehicle factory in the Anhui Province of China, DYD achieved impressive cost and time savings while also setting new sustainability benchmarks. With a workflow that included Autodesk Forma, AutoCAD, Revit, Inventor, NavisWorks, FlexSim, and 3ds Max, the company used AI to optimize everything from factory planning to 3D modeling to environmental simulation and construction. The results were telling with a reduction in carbon emissions of nearly twenty thousand tons per year.

Media & Entertainment (M&E)

Innovator of the Year: Boxel Studios

Boxel Studio is always exploring how to redefine what’s possible in visual effects and animation. This was clearly evident with their new implementation of AI-powered motion capture technology in Autodesk Flow Studio to optimize its visual effects pipeline.

Using Flow Studio, the Boxel team delivered a high volume of creature animation for Superman & Lois Season 4, all on a fast-paced production schedule. By combining traditional tools with AI, Boxel streamlined their VFX pipeline, allowing them to create content more efficiently without compromising quality.

One of the many creatures created by Innovator of the Year Award winner Boxel Studio. Image courtesy of Warner Brothers and Boxel Studio.

Accelerating Transformation: ShadowMachine

ShadowMachine is known for pushing the boundaries of stop-motion animation. But dynamic changes are an everyday reality in stop-motion productions. ShadowMachine has now built a collaborative production environment to streamline communications and unlock new levels of efficiency using Autodesk Flow Production Tracking and Flow Capture. They can map out timelines and workflows with clarity and adjust resources before disruptions occur, building smarter, more connected workflows that fuel creativity and growth.

Making a Better World: AfroVX

AfroVFX is redefining the future of visual effects and animation across Africa by providing free, professional 3D and VFX education to aspiring artists across the continent, fostering a new generation of storytellers and creators. By building bridges between African ecosystems and the global 3D industry, they are unlocking world-class talent and nurturing a vibrant community. AfroVFX is taking a giant leap toward making Africa a global hub for animation and visual effects

Education

Education Excellence

Each year, under the instruction of Joe Buro and Katie Geraghty, hundreds of students at Staten Island Technical High School earn professional certifications in AutoCAD, Revit, 3ds Max, and Fusion. But what sets the program apart is its focus on the impact that design can have on people’s lives. From designing community gardens in Revit to designing textured button covers for blind students in Inventor, students build their skills by focusing on real-world applications. They even design and manufacture a skull implant based on Joseph’s own implant. Education with Joseph and Katie isn’t just about mastering tools. It’s about applying them in the real world and to make a difference.

Community Leader of the Year

AEC Community Leader of the Year: Shelby L. Smith

Shelby L. Smith, CIM Manager at JMT in Pennsylvania, exemplifies this award through her wide-ranging contributions, including supporting the C4C3D User Group, writing for the Autodesk Community, developing Civil 3D exams, and presenting at AU. Known for her ability to simplify complex topics, she fosters environments where collaboration and learning take priority over expertise. In a constantly changing field, Smith stands out as someone who not only adapts but also guides others through transformation with clarity and purpose.

D&M Community Leader of the Year: Kevin Kennedy

With more than 326 thousand subscribers and 30 million views, Kevin Kennedy has helped countless people discover and master Autodesk Fusion, making his YouTube channel, Product Design Online, one of the most influential in the community. A professional product designer and CAD educator, he also creates free resources, runs forums, and personally helps members of the community. Kennedy isn’t just teaching CAD—he’s building a welcoming, thriving community.

M&E Community Leader of the Year: Paul Neale

With nearly 30 years in 3D animation, Paul Neale has worked as a technical director and rigging and modeling specialist across film, TV, and triple-A games. Equally passionate about teaching, he is a professor for the animation program at Humber College and has led sessions at SIGGRAPH, GDC, and AU. On YouTube, his tutorials and workflows have attracted over 14,000 subscribers and more than a million views. Paul proves that true community is not just about what you create, but what you share.

Outstanding Recognition

Outstanding Recognition ASEAN: PT PP Persero

The new Presidential Palace is a pivotal project in the capital relocation efforts of Indonesia’s capital to Nusantara. The project represents not only an important new building for the country, but also PT PP Persero’s expanding work with BIM. To complete construction for Indonesia’s Independence Day, the team needed to accelerate every step of the process, from design and review to construction and handover. The team used the Autodesk Platform to hit the date, as well as improve the use of BIM moving forward.

View of the Presidential Palace in Nusantara, Indonesia. Courtesy of PT PP Persero.

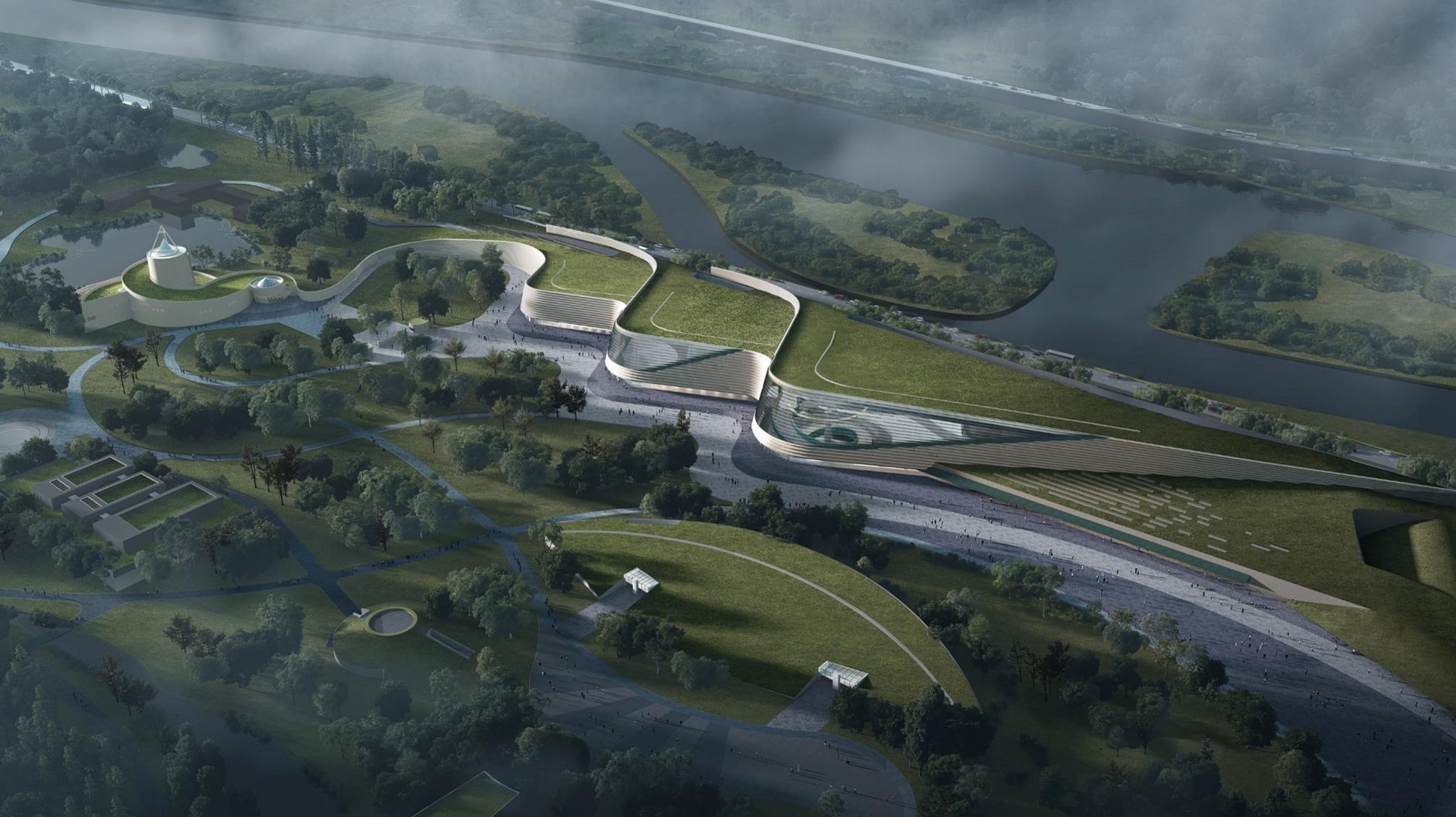

Outstanding Recognition China: China Construction Eighth Engineering Division

The Sanxingdui Museum was built near the same spot where ancient Shu artifacts were uncovered, including a three-thousand-year-old gold mask. China Construction Eighth Engineering Group led a remarkable undertaking for construction of the museum to preserve and honor the artifacts found there. Using a connected digital workflow from design through operations including a digital twin, China Construction Eighth Engineering Division cut the timeline from 36 to 16 months, saved 20 million yuan, and reduced material waste by 23 percent. The team also generated digital replicas of 1500 artifacts, powering an immersive virtual museum that’s attracted millions of online visitors worldwide.

Aerial rendering of the Sanxingdui Museum. Courtesy of China Construction Eighth Engineering Group.

Outstanding Recognition India: Sansera

Sansera, a global precision parts manufacturer based in India, knows the challenges facing automotive manufacturers: bringing new vehicles to market faster and without compromising quality. They’re helping to solve this by automating design processes using iLogic in Autodesk Inventor. Creating designs for parts used to take two or three days with manual processes and relied heavily on designer expertise. Using iLogic, the team can do the same work in 30 minutes with fewer errors, less rework, and fully standardized outputs, even with less skilled designers in charge. Now, Sansera can scale its design and production to meet the needs of their customers.

Looking ahead

At Autodesk, we’re proud to partner with some of the world’s most visionary designers, makers, and innovators. Together, we’ll keep pushing the limits of what’s possible and inspire the next generation to do the same. Stay tuned and bookmark this page for the chance to submit your own incredible work next year.